- THE UNSCRAMBLER X BY CAMO SOFTWARE HOW TO

- THE UNSCRAMBLER X BY CAMO SOFTWARE SOFTWARE

- THE UNSCRAMBLER X BY CAMO SOFTWARE PLUS

It enables multivariate models to be applied to on-line, at-line and in-line processes.

THE UNSCRAMBLER X BY CAMO SOFTWARE SOFTWARE

Unscrambler® X Process Pulse II’s real-time process monitoring software lets you predict, identify and correct deviations in a process, before they become problems.

THE UNSCRAMBLER X BY CAMO SOFTWARE PLUS

It includes powerful regression, classification and exploratory data analysis tools, plus an integrated design of experiments module. Unscrambler X is a leading multivariate analysis software suite used by thousands of engineers, data analysts around the world every day. Established in Oslo in 1984 and with offices in the US, Japan, Australia, the UK, and India, CAMO is the creator of The Unscrambler® X suite of products used by chemical manufacturers worldwide. Multivariate data analysis softwareĬAMO Software specialises in multivariate data analysis software and solutions. spectrometers) or integrated with control systems for use by process operators. The solutions can be used standalone to analyse off-line data, connected to databases or scientific instruments (e.g. This enables them to:ĬAMO’s solutions allow multivariate models to be developed by technical service groups or CAMO’s consultants, and then applied to real-time production processes. Multivariate analysis tools allow engineers and production managers to better understand process behaviour and implement more robust control strategies. Univariate statistics tend to fail when analysing complex systems because they cannot detect relationships between the variables, often the cause of process upsets. Yet most statistical process control (SPC) systems rely on univariate methods, which only look at single variables, one at a time.

a large number of variables which are usually interactive – they require multiple measurements to fully understand them. Multivariate analysis in food productionīecause food manufacturing processes are typically highly multivariate in nature – i.e.

This is now changing as manufacturers realise that the masses of data collected during production operations offer an insight into ways to improve product development and process performance. Multivariate data analysis methods have been around for decades, but until recently were primarily used in laboratories and technical groups, rarely being applied to production processes. Multivariate data analysis (MVA) is the investigation of many variables simultaneously, to understand the relationships that may exist between them. With the need to reduce costs and improve product safety, powerful tools traditionally used by analytical groups are being transferred to the plant floor. If you have any questions, please email the Diamond Events Team at or call 01235 778431.Advanced analytics are helping food manufacturers reduce process failures and improve yields and quality.

THE UNSCRAMBLER X BY CAMO SOFTWARE HOW TO

Please see the Delegate Information page for futher details on the course and how to apply.įUNDED ACCOMMODATION FOR JUNIOR SCIENTISTS/STUDENTS IS AVAILABLE

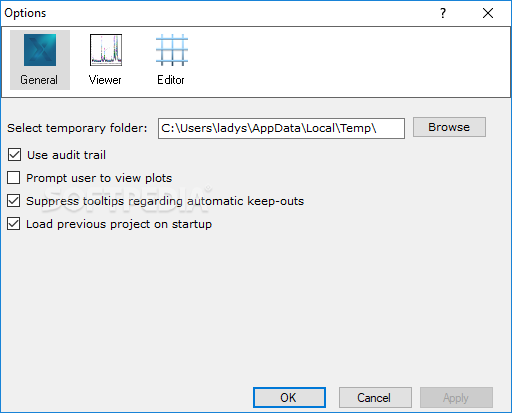

It will concentrate on the hands-on use of The Unscrambler X software for mid-infrared spectra analysis, preceded by a general introduction to multivariate analysis. The training is a 2-day course on multivariate data analysis for infrared microspectroscopy intended for current and future users of the MIRIAM beamline B22 at Diamond in multidisciplinary applications. No prior knowledge of multivariate methods is required and it is aimed at researchers working with vibrational spectroscopy (IR and Raman) in order to provide a firm basis for working with multivariate methods and hands on training in the use of the dedicated analysis software. A multipurpose introductory course into CAMO Unscrambler X is being offered as part of the Multivariate IR Microspectroscopy Analysis training being organised by the B22 beamline.

0 kommentar(er)

0 kommentar(er)